Description

Half Dome Stainless Steel Anti-Ligature Mirror

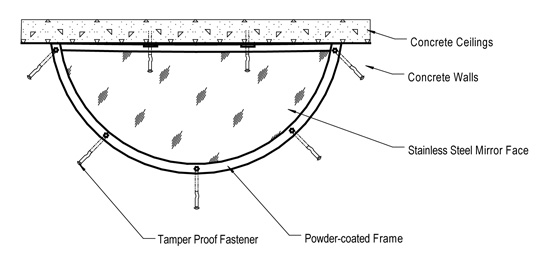

The DuraVision Stainless Steel Half Dome is manufactured from highly polished mirror grade stainless steel. The Half Dome has a 180 degree wide angle reflection and when optimally positioned the entire cell can be viewed at a glance from the observation window. The unique frame and hole design make this mirror strong, effective and virtually ligature free.

Features

- Virtually indestructible and unbreakable mirror quality polished stainless steel face, designed to maximise the viewing area which will provide added safety

- Counter-Sunk and Counter-Step holes designed to take security head fasteners such as Rawl Spikes or Torx Screws

- The mirror can be locked into a unique steel frame which ensures the risk of the mirror being tampered with is reduced significantly.

- Virtually a maintenance free, long lasting, unbreakable surveillance system.

Download Information Sheet pdf.

Download Information Sheet pdf.

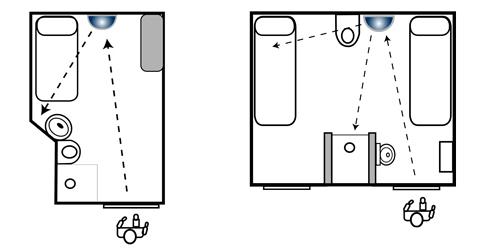

Positioning

Specifications:

| Product Code | Size | Mirror Face | View Distance | Fixing Holes | Frame Colour |

|---|---|---|---|---|---|

| 16529HD | 500mm 20" | 1mm Stainless Steel | Up to 5m | 6 | Grey |

Installation Guide

Half Dome Stainless Steel Cell Mirror Installation

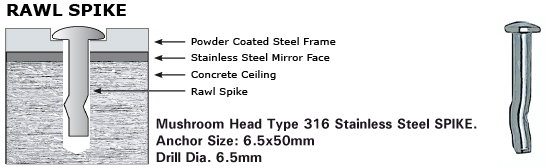

NOTE: If installing with Rawl Spikes, it is recommended to use a punch. This is to eliminate damage to the mirror face or the powder-coated frame.

OPTIONAL: Finish off by applying a bead of non-pick sealant around the mirror or frame and the wall to prevent the secretion of small objects (eg razor blades etc).

Download Installation Guide pdf.

Download Installation Guide pdf.

Suggested Fastening Methods

Installation: Drill a hole into the base material to a depth of at least 60mm.The tolerances of the drill bit used should meet the requirements of ISO/DIN Standard 8035. Blow the hole clean of dust and other material. Drive the Spike through the appropriate mirror face hole (and frame when used) ensuring the head is sitting firmly against the mirror or frame and recessed as shown in the above diagram.

Installation: Drill a hole into the base material to a depth of at least 60mm.The tolerances of the drill bit used should meet the requirements of ISO/DIN Standard 8035. Blow the hole clean of dust and other material. Drive the Spike through the appropriate mirror face hole (and frame when used) ensuring the head is sitting firmly against the mirror or frame and recessed as shown in the above diagram.

NOTE: Care should be taken not to overdrive the Spike so as to cause damage to the powder coated surface of the frame.

DuraVision Rawl Spike Punch: The DuraVision designed punch for inserting spikes can significantly reduce the risk of damaging the mirror face or frame during installation.

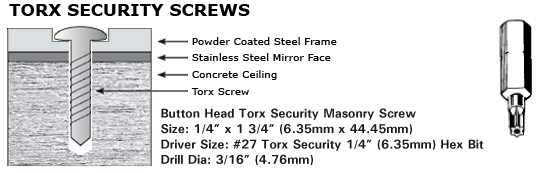

Installation: It is recommended to use a 3/16” (4.76mm) Straight Shank Tanged Bit to drill the hole. The hole must be at least 2” or 50mm overall depth and free of any debris. By using the #27, 1/4” (6.35mm) Hex Bit the special Hi-Lo thread literally taps into masonry materials. The high,sharp thread with its notched cutting edge cuts deeply and easily. The alternating low thread provides stabilty for fast, accurate driving. Torx Tamperproof masonry screws are the optimal fastening solution for use in concrete, brick, or hollow block.

Installation: It is recommended to use a 3/16” (4.76mm) Straight Shank Tanged Bit to drill the hole. The hole must be at least 2” or 50mm overall depth and free of any debris. By using the #27, 1/4” (6.35mm) Hex Bit the special Hi-Lo thread literally taps into masonry materials. The high,sharp thread with its notched cutting edge cuts deeply and easily. The alternating low thread provides stabilty for fast, accurate driving. Torx Tamperproof masonry screws are the optimal fastening solution for use in concrete, brick, or hollow block.

Cleaning Guide

Stainless Steel Mirror Cleaning Guide:

General Cleaning:

Bennett Mirror Technologies recommend cleanning their Stainless Steel Mirrors with soap and water and then with a soft, lint free, damp cloth.

DO NOT USE:

- abrasives

- acids

Polish:

Bennett Mirror Technologies does not recommend using a commercial Stainless Steel Polish, as the protective layer will leave a residue on the highly polished mirror faces. Rubbing plain white flour on a dry stainless steel mirror face with a dry cloth will polish the mirror to its original brilliance.

Graffiti Removal:

Any graffiti should be removed from the mirror face as soon as possible and preferably within 24 hours with a suitable lacquer thinners. Not all graffiti cleaning agents are suitable. Failure to use an approved cleaning agent may damage the mirror surface.